WCPC Acquires New Kit to Cure Printed Electronic Inks

The Welsh Centre for Printing and Coating (WCPC) and Swansea Univeristy’s College of Engineering has partnered with NovaCentrix to install a specialist system to cure printed electronic inks.

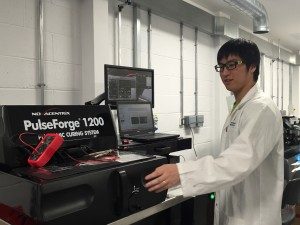

The Welsh Centre for Printing and Coating (WCPC) and Swansea Univeristy’s College of Engineering has partnered with NovaCentrix to install a specialist system to cure printed electronic inks. The NovaCentrix PulseForge 1200, designed for the high speed photonic cure, is available in the open access WCPC laboratories. The equipment has already been put to work on projects for printed Radio Frequency Identification (RFID) and Near Field Communication (NFC) antennas for smart packaging and assisted living applications.

Photonic curing is a high-intensity pulsed light technology enabling conductive inks to be sintered or annealed in a matter of milliseconds. The sintering of the ink occurs with minimal or no damage to inexpensive and flexible substrates such as plastic, paper or cardboard. Scale up for production of items such as wearable electronics and medical sensors can immediately be applied to volume production using the PulseForge platforms already available and in use for manufacturing of products sold world-wide.

Professor Tim Claypole MBE states, “The existing expertise at the WCPC in all forms of printing can only be enhanced by our partnership with NovaCentrix and the installation of the PulseForge 1200 will aid research within the WCPC. We are also pleased that NovaCentrix have agreed to provide workshops at our Cost Action Summer School in July. “

Stan Farnsworth, VP Marketing at NovaCentrix adds, “We are honored that Professor Tim Claypole and the WCPC have determined that the state-of-the-art capabilities of the PulseForge 1200 photonic curing tool can support their efforts in achieving their research and development goals. Education is a key priority for us as well, being particularly delighted to support the WCPC community through ongoing operational and process training related to the PulseForge tool. Additionally, the ‘Cost Action Summer School’ will be an important venue for our technical staff to be able to share our knowledge of photonic curing within printed electronics to a new generation of engineers and scientists.”